Oxygenation Technology

The Pressurized Packed Column (PPC) is a highly effective oxygenation technology for use in aquaculture applications. A PPC consists of a pressure vessel filled with packing media, a pump, control mechanisms for oxygen addition and pressure relief, and interconnective plumbing. The PPC provides an environment of rapid gas exchange by increasing both the partial pressure of oxygen, and by increasing the gas-liquid surface area.

From Pressure to Performance: How PPC Design Maximizes Gas Absorption

By Henry's Law, the solubility of a gas in a liquid is directly proportional to the pressure of that gas at the surface of the liquid. Due to the elevated pressure inside the vessel, and the injection of pure oxygen gas, the partial pressure of oxygen within a PPC can be as much as 50x that of oxygen in atmospheric air. The elevated partial pressure is the motive force driving both the speed of gas transfer and the total amount of gas that may potentially be absorbed.

For example, at an operating pressure of 100 psig of an oxygen rich atmosphere, the saturation concentration of oxygen in freshwater at 10degC is 416 mg/L compared to 11 mg/L at normal atmospheric conditions. The saturation concentration within the vessel represents the maximum potential gas that may be transferred into the water.

This potential is realized only when you also provide the opportunity for the gas transfer to occur. The use of random packing media inside the PPC vessel break water into droplets and thin films, increasing the contact between gas and liquid. The height of the packing bed, which is defined by total vessel height and the water level within the vessel, also affects the total contact time. Packing bed depth in a PPC is typically greater than 1.5 m (60 in).

As a result of high pressure and high packing depth, PPCs can achieve very high oxygen supersaturation levels (commonly >2000% of saturation at atmospheric conditions) at a very high transfer efficiency (>98%). Addition advantages of PPCs including a low footprint (due to a high hydraulic loading rate), and rapid response to changing oxygen flow rates (which allows for automated operation in response to dissolved oxygen levels).

The disadvantages of PPCs include relatively high capital cost, energy requirement, and complexity. However, when applied appropriately, these disadvantages may be diminished and the PPC can be one of the most cost-effective oxygenation solutions for aquaculture facilities.

Application

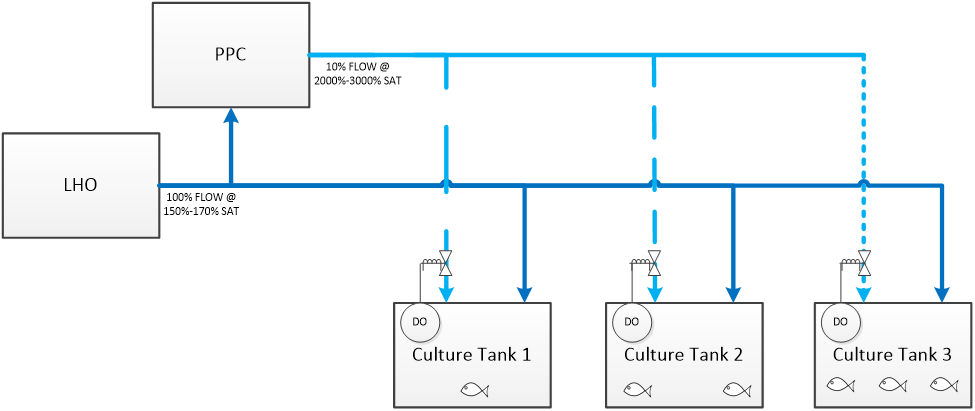

A typical application is to use a PPC to achieve a very high oxygen level in a small side stream flow, and then either blend the oxygenated water with the main process flow or deliver it directly to the culture tanks. Care must be taken in design to ensure that off-gassing does not occur in the conveyance piping after oxygenation. Often it is advantageous to have the injection point as close as possible to the fish tank (or direct into the fish tank) to limit potential for off-gassing.

At PR Aqua, one of our preferred oxygenation strategies for RAS involves the use of PPC in combination Low Head Oxygenator (LHO).

A Cost Effective Method

The LHO, which operates at less than 1.0 m of hydraulic head, is a cost-effective method of achieving moderate oxygen levels in large flows. Because of its low operating pressure, the LHO also has the ability to displace dissolved nitrogen as oxygen is added, providing protection against nitrogen supersaturation and allowing the use of low-cost generated oxygen (which has an elevated nitrogen content). However, LHO are slow to respond when operating conditions change and they perform best when both water and oxygen flow rates are consistent. The LHO is most effective when installed centrally and used for setting a consistent baseline oxygen level for all culture tanks. Another technology is required for responding to the rapid fluctuations in oxygen demand that can occur at each tank during feeding, by diurnal variations in fish activity, or during fish transfer and other stress events.

The PPC is an optimal choice for this application as it responds very rapidly and may be self-modulated to maintain consistent oxygen levels. The PPC is generally installed to provide highly oxygenated water through dedicated distribution piping for injection at each culture tank. Solenoid valves at each tank automatically open as required based on dissolved oxygen monitoring at that tank. As valves open and close, pressure changes in the distribution piping cause the PPC pump speed to automatically adjust, maintaining the target pressure within the PPC vessel to ensure optimum conditions for oxygen transfer. Oxygen flow into the vessel is also automatically regulated based on the rate of oxygen absorption which is indicated by the water level within the vessel.

The Benefits of the Technology

This combination of high pressure and lower pressure oxygenation technologies has been found to be highly effective in optimizing capital and operating costs while realizing all the benefits of each individual technology.

- The LHO provides much of the oxygen load at very low operating pressure, allowing the size and cost of the PPC to be minimized.

- Because the PPC manages the variable load at the tanks, the LHO may be operated under stable operating conditions and at its peak oxygen transfer efficiency.

- The energy intensive high-pressure pumps associated with the PPC only operate as much as required, turning down or off to conserve energy when oxygen demand is low.

- High pressure operation of the PPC allows for downsizing of expensive control valves for injection of oxygenated water at the tanks.

- The LHO may also be used for ozone contact, for control of dissolved nitrogen levels, and may be used with generated oxygen for further operating cost reduction.

Case Study

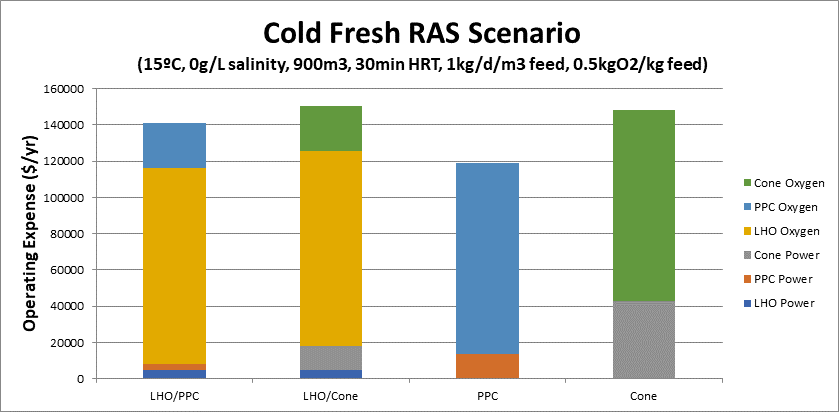

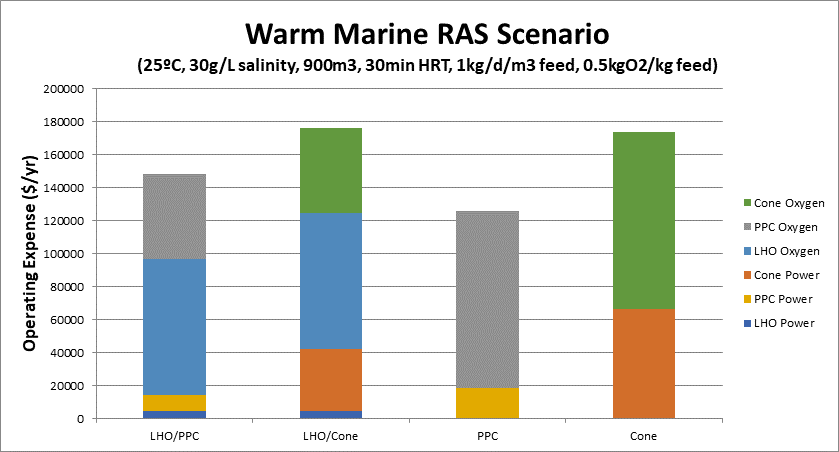

The following case study compares the operating expense of various oxygenation device configurations for both cold freshwater and warm marine scenarios. The operating expense assumptions were based on oxygen and electrical usage at rates local to Vancouver Island, BC, Canada($0.65/kg O2 and $0.10/kWh). Mechanical generation of oxygen was not considered in this study.

The facility considered would be typical of a smolt production (15ºC, 0ppt salinity) or marine grow-out (25ºC, 30ppt salinity) module, consisting of a culture volume of 900m3, turning over at a rate of two (2) culture volumes per hour (30min HRT). A feed rate of 1.0kg/d/m3 culture volume is assumed, with an oxygen consumption rate of 0.5kg O2/kg feed (by fish). It is assumed that aeration treatments upstream of oxygenation will achieve 95% DO saturation, while the mixed tank oxygen concentration will be maintained at 90% saturation.

The case study considers the use of a Low Head Oxygenator (LHO), Oxygen Cone, and Pressurized Packed Column (PPC) in various combinations. The specific configurations compared include LHO/PPC pairing, LHO/Cone pairing, PPC only, and Cone only.

Where LHOs were utilized, they were assumed to provide a 170% saturation baseline oxygen concentration. These were assumed to operate with a water level differential of 0.85m (2.3ft) – inclusive of orifice stand over and fall height. RAS recirculation pumps were considered to operate at 75% efficiency while PPC and Oxygen Cone pumps have an assumed operating efficiency of 70%.

The graphical results indicate that for both cold fresh and warm marine scenarios, the PPC has the lowest operating cost of the four oxygenation configurations analyzed. The LHO/PPC pairing operates with the lowest power consumption, followed by the PPC, LHO/Cone pairing and the Cone. Oxygen usage is similar for both the PPC and Cone, while the LHO consumes more oxygen (lower transfer efficiency).

While the results shown are specific to resource costs for Vancouver Island, BC. In all cases the PPC or PPC/LHO pairing will have the lowest operating cost independent of regional resource cost variations. However, the other benefits of the LHO/PPC pairing (as discuss above) generally makes this solution more advantageous overall for RAS applications.

For more information about the PPC, visit the product page or contact us for inquiries.